Our latest 3D printers are making huge models...models that sometimes take a few days to complete and a lot of filament to produce. For larger prints we recommend using a large spool of filament (5+ lb. spools). However, if a large spool is not available to you you can also bind multiple smaller filament rolls at their ends so that they create one continuous line of filament. Unfortunately, there is no way to do this on spooled filament before a print so your only option is to stay vigilant over your print and recognize the best time to perform this procedure while the printer is in operation.

NOTE* This is not an easy procedure to accomplish. We only recommend doing this if it's absolutely necessary as it's very difficult to accomplish this while the printer is in operation. Please practice this before attempting on a real print.

The following pictures show how you can join two filament ends using PTFE tubing and a regular lighter/match. To do this you're going to need a piece of PTFE tubing, two filament ends, and a heat source (matches/lighter/extruder heater).

NOTE* In order for this to work the inner diameter (ID) of your PTFE tubing needs to be very close to the width/diameter of your filament. In addition, your PTFE tubing needs to have .5mm walls...if the walls of the tubing are too thick you will not be able to heat the filament enough without burning the PTFE tubing.

We recommend the following sizes:

3mm Filament: PTFE Tubing with 3mm ID & 4mm OD (or 3.5mm ID & 4.5mm OD)

1.75mm Filament: PTFE Tubing with 2mm ID & 3mm OD

Cut the ends of your filament so that they are flush with one another.

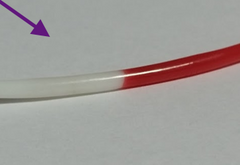

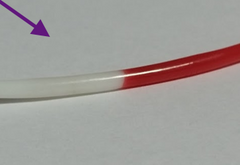

Push both ends of your filament into the PTFE tube so that they meet at the middle.

Use a lighter or match to carefully heat the point where the two filament ends meet. WAVE THE FLAME BACK AND FORTH. DO NOT LEAVE THE HEAT SOURCE/FLAME UNDER THE PTFE FOR A LONG TIME. A very small amount of heat for a short amount of time should do the trick to soften the filament and make a solid joint. The PTFE has a higher melting point than your filament (PLA & ABS) so if you are careful it will not melt but will still allow your filament to melt on the inside.

You will know when you are doing this correctly because the filament will appear to stick to the insides of the PTFE tubing. However, once your filament cools off (it only takes a few seconds to cool off) you will be able to slide it through easily.

Works with ABS:

Works with PLA:

There are two downsides/issues with this procedure: 1. You will have to do this while your printer is operational and still pulling in filament. This means that you need to anticipate when your first filament spool is going to end so that you can be there to bind the filament ends. 2. Because you are binding the second filament while it is on a new spool there is no way to remove the PTFE tubing after you have bound the old and new filament ends. This will result in the PTFE tubing being your new best friend and hanging out with you throughout the rest of your printing with that spool.

You will want to make sure that before you attempt doing this that the PTFE tubing's diameter is of sufficient width to not get sucked up into the filament feeder. If your PTFE is in danger of being sucked in you might want to put a washer in front of the tubing BEFORE STARTING THIS PROCEDURE to keep it out of the filament feeder.

If you absolutely do not want to leave the PTFE tubing over your filament you can take a razor blade and cut off the small piece of PTFE tubing.