Jabil

:The biggest company you've never heard of....

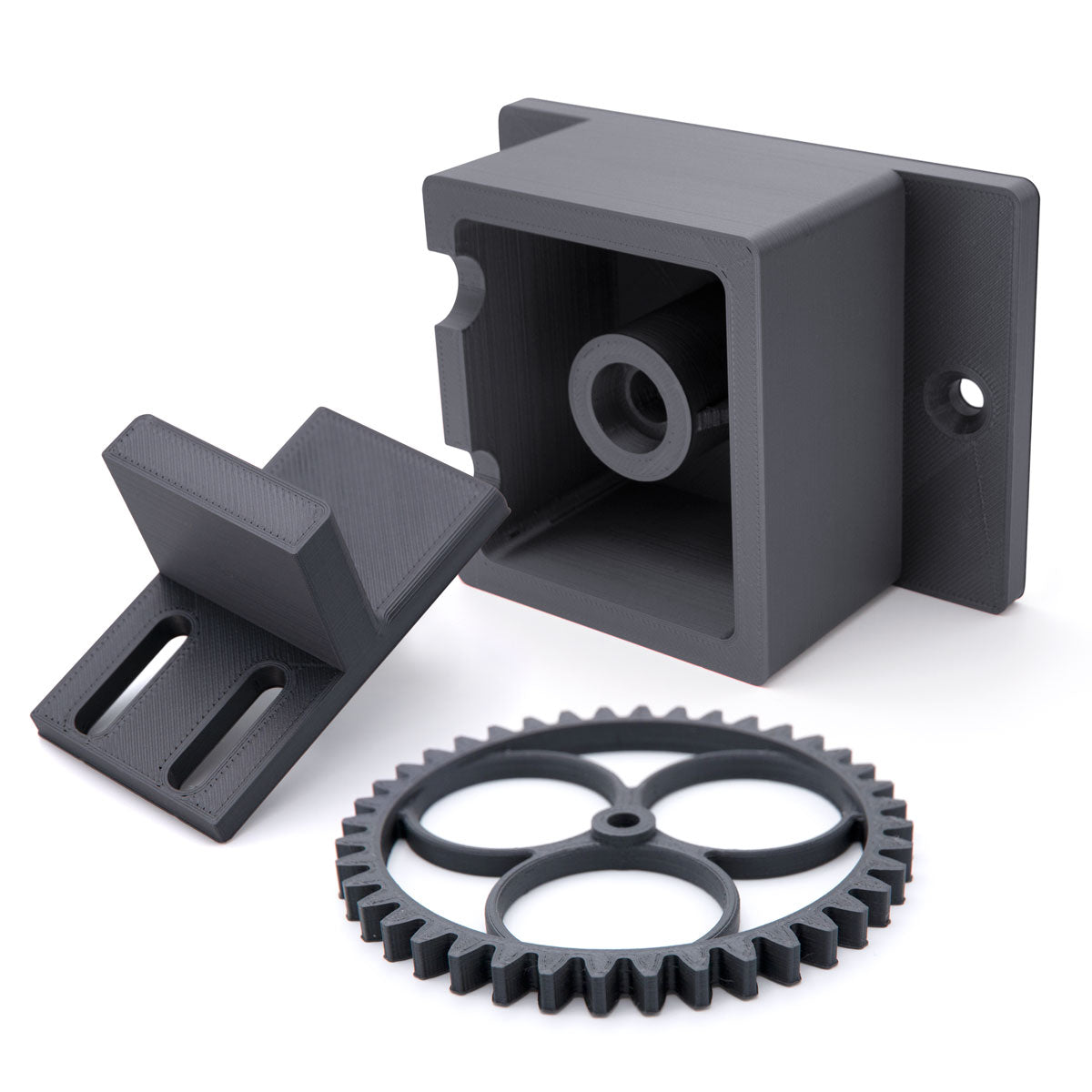

Jabil Additive is a flexible, high-velocity partner that meets specialized materials requirements, helping customers improve how they design, make and deliver products. From ideation to industrialization Jabil: enables design freedom, accelerates time-to-market and ensures compliance to industry certifications. Jabil’s Minnesota-based Innovation Center is at the forefront of the industry, formulating and producing high-quality materials. Jabil Additive is improving existing polymers and creating new ones. Jabil chemists, material scientists and additive manufacturing experts are developing filaments, powders, pellets and custom materials featuring unique and enhanced properties.

- Made by Experts for Experts -

Jabil, in addition to advancements in materials, continues to extend its global additive manufacturing platforms and solutions to complement its world-class manufacturing capabilities. Jabil has deployed hundreds of 3D printers-from desktop models to highly sophisticated industrial systems-to address a vast range of prototyping, tooling and volume-scale production demands.

Enginneering Grade Filament

Jabil produces high-quality filament materials with unique properties such as increased strength, flame retardancy, conductivity and lubrication. Jabil's filament materials deliver high strength and stiffness required for demanding aerospace, automotive and industrial manufacturing applications.

What characteristics are you looking for?

Jabil ABS 1400 LW

- Stiffer than most ABS filament

- Reduced CLTE (continuous level, linear thermal expansion)

- Good chemical resistance to most fluids

- Stands up to finishing processes

Jabil PA 0600

- Excellent machinability

- Good wear and abrasion resistance

- High strength and stiffness

- Low coefficient of friction

- Excellent chemical resistance.

- Non-marring

Jabil PA 4035 CF

- High strength, stiffness and toughness

- Superior printed part surface finish quality

- Surface resistivity of ≤E9 for ESD sensitive applications

- Mechanical properties can be tailored by adjusting fill orientation.

Jabil PA 4500

- Over 100% elongation at break

- Low temperature processing temps (240-260° C)

- Superior strength compared to other commercial PA's

- Good blend of appearance and strength capabilities

Jabil PA 4535 CF

- Electrostatic dissipative (ESD)

- No reduced impact strength

- Improved Z layer properties

- 40% increase in stiffness and tensile strength over lower carbon fiber-loaded products

Jabil PC 1500 FR

- Flame retardancy

- Self-extinguishing properties

- Stiff w/ excellent impact strength and ductility

- High impact resistance

- Demonstrates V-0 burn properties

Jabil PETg

- Easy printability, low shrinkage and warpage

- Excellent Chemical Resistance

- Good Strength and stiffness

- Non-marring

- Robust post-processing potential

Jabil PETg 0800 ESD

- ESD properties - ESD of 10E5-10E9

- Excellent Chemical Resistance

- Good Strength and stiffness

- Low shrinkage and warpage

Jabil PLA 3100

- Ease of use

- Low thermal requirements

- Very consistent lot-to-lot print properties

- Good Strength and stiffness

Jabil TPE-SEBS 1300 85A

- Easier to print than TPU filament

- High flexibility, bend and stretch (can stretch over 500%)

- Low moisture absorption

- Does not require drying to process

Jabil TPE-SEBS 1300 95A

- No need for heated print bed or drying requirements

- High flexibility, bend and stretch

- Non-hygroscopic, does not absorb moisture

- Durable with repetitive motions

Jabil TPU 90A

- Easy printability, very consistent results

- Abrasion resistance

- Elastomeric properties

- Good chemical resistance to oils, greases, and other solvents

Compare Materials

Jabil Powders

| View Powders | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| UTS (Mpa) Orientation |

Tensile Modulus (Mpa) Orientation |

EaB (%) Orientation |

Unnotched Impact Energy (J/m) Orientation |

Notched Impact Energy (J/m) Orientation |

Melt Temperature (°C) |

||||

| Material | XY | Z | XY | Z | XY | z | XY | XY | |

| PA 4000 | 46 | 37 | 1790 | 1130 | 34 | 12 | 1010 | 48 | 182 |

| PA 4050 GB | 44 | 46 | 3390 | 3380 | 6 | 5 | 221 | 33 | 181 |

| PK 5000 | 53 | 51 | 1305 | 1349 | 41 | 21 | 1241 | 83 | 197 |

Jabil Filament

| View Filaments | ||||||

|---|---|---|---|---|---|---|

| UTS (MPa) Orientation |

Tensile Modulus (MPa) Orientation |

EaB (%) Orientation |

Unnotched Impact Energy (J/m) Orientation |

Notched Impact Energy (J/m) Orientation |

Melt Temperature (°C) |

|

| Material | XY | XY | XY | XY | XY | XY |

| ABS 1400 LW | 35 | 2730 | 3 | 235 | 39 | N/A |

| PA 0600 | 49 | 2660 | 5 | 822 | 69 | 188 |

| PA 4035 CF | 66 | 6000 | 4 | 557 | 191 | 180 |

| PA 4500 | 56 | 1930 | > 100 | 830 | 62 | 190 |

| PA 4535 CF | 88 | 10600 | 3 | 525 | 125 | 190 |

| PC 1500 FR | 61 | 2210 | 6 | 850 | 51 | N/A |

| PETg | 45 | 1655 | 24 | N/A | N/A | N/A |

| PETg 0800 ESD | 39 | 1895 | 8 | 416 | 49 | N/A |

| PLA 3100 | 47 | 3240 | 6 | 207 | 31 | 155 |

| TPE SEBS 1300 85A | 6 | 19 | 900 | N/A | N/A | 163 |

| TPE SEBS 1300 95A | 11 | 93 | 780 | N/A | N/A | 165 |

| TPU 90A | 19 | 13 | 4540 | N/A | N/A | 220 |

$ 32.50

$ 64.99

$ 26.25

$ 52.50

$ 44.99

$ 89.99

$ 35.99

$ 71.99

$ 10.99

$ 21.99

$ 10.99

$ 21.99

$ 26.25

$ 52.50

$ 26.25

$ 52.50

$ 25.99

$ 51.99

$ 26.25

$ 52.50

$ 35.99

$ 71.99

$ 10.99

$ 21.99

$ 32.99

$ 65.99

$ 35.99

$ 71.99

$ 32.99

$ 65.99

$ 25.99

$ 51.99

$ 10.99

$ 21.99

$ 10.99

$ 21.99

$ 10.99

$ 21.99

$ 25.99

$ 51.99

$ 10.99

$ 21.99

$ 900.00

$ 42.49

$ 89.99