LulzBot Mini 2

a fantastic choice for professionals and educators

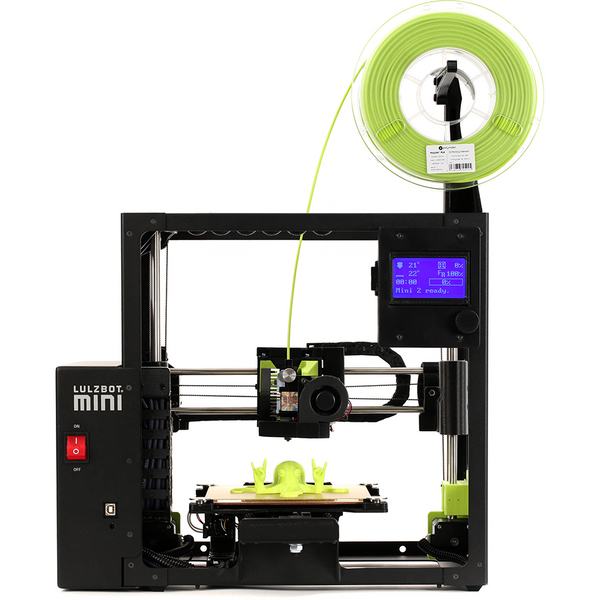

The compact and powerful LulzBot Mini 2 features numerous updates and upgrades, making it a fantastic choice for professionals and educators looking for a portable workhorse for the office, shop, and classroom.

Small Size, Big Capabilities

Major hardware improvements over the original LulzBot Mini include Einsy RAMBo electronics with Trinamic drivers for whisper-quiet operation and a build volume increase of approximately 20% with no increase in footprint.

But Wait, There's More

The Mini 2 features a belt-driven Z-axis which allows for rapid travel and accurate layer alignment, with no reduction in minimum resolution. Also included as standard equipment are three accessories previously offered as add-ons to the original LulzBot Mini: A next generation Tool Head designed around the E3D Titan Aero hot end and extruder, capable of printing both rigid and flexible filaments out of the box, the LulzBot modular bed system with reversible heated glass/PEI surface, and a Graphical LCD Controller for tetherless operation.

Libre Innovation

All LulzBot products use Free Software and are Open Source Hardware. This means your LulzBot Mini uses proven technology developed collaboratively. Cura LulzBot Edition version 3.2 software is now in a public beta phase, and is anticipated for a final release in advance of the first shipments of Mini 2 units. The update to Cura LE features faster load times, an updated interface, and a bevy of new slicing options.

Technical Specs

Print Technology |

FFF |

Build Volume |

16 x 16 x 18 cm [6.3 x 6.3 x 7.09 in]4608 cm3 [281.4 in3] |

Filament Diameter |

2.85mm |

Supported Material |

Open filament system compatible with PLA, Natural and Metal PLA Blends, TPU, ABS, PETG, nGen, INOVA-1800, HIPS, HT, t-glase, Alloy 910, Polyamide, Nylon 645, Polycarbonate, PC-Max, PC+PBT, PC-ABS Alloy, PCTPE, and more |

Build Platform |

Heated borosilicate glass bed covered with PEI print surfacePrint Bed Temperature: 120 C [248 F]

|

Print Bed Leveling |

Automatic Compensation |

Extruders |

Single, E3D Titan Aero Hot EndMaximum Nozzle Temperature: 290 C [554 F]Nozzle Heatup Time: From 23 to 210 C (73 to 410 F) in 73 seconds |

Layer Resolution |

50-400 microns |

Max Travel Speed |

300 mm/s |

Nozzle Diameter |

.5mm |

Nozzle Material |

Nickel-Plated Copper Alloy |

Supported File Types |

STL, OBJ, X3D, 3MF, PNG, JPG |

Operating Software |

Cura LulzBot Edition Version 3.2 or newer |

Firmware |

Marlin |

Supported OS |

GNU/Linux

|