REMOVING AND CHANGING A STEPPER MOTOR DRIVER

Be sure to power OFF and unplug your printer before removing any electronic components.

Your printer's axes move via power provided to stepper motors. These stepper motors have gears on them that pull or push the bands that are attached to your gantry mounts...thus moving your extruder carriage assembly in different directions. Stepper Motors require a specific amount of power for a specific operation...this is where stepper motor drivers come into play. These chips keep the power that drives the motors separate from the power that is on the micro-controller. The micro-controller can't provide proper power to the stepper motors directly. This is why you have to use separate chips to act as "valves" that control how the motor spins.

Another benefit that stepper motor drivers provide is the provision of fractional steps. This helps smooth out the rotating motion of the stepper motor. Without fractional steps stepper motors would have a tendency to vibrate or resonate at certain RPMs.

Your stepper motor drivers are located on the micro-controller that is housed underneath your printer. You will need to remove the printer's bottom electronic's panel in order to view and replace your stepper motor drivers. Using your 2.5mm hex key, remove the screw highlighted by the green arrow below. Once removed, place the panel, the small screw, and the nut in a secure place.

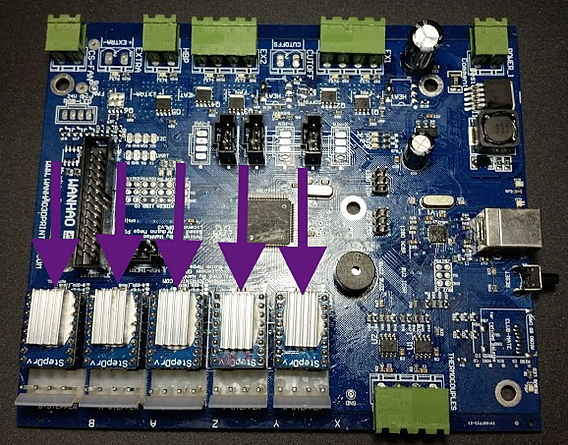

Your Duplicator 4 series printer has 5 stepper motor drivers on it's micro-controller. These are highlighted by the green arrows below. Each one corresponds to the stepper motor whose letter is labeled right next to the stepper motor slot. For Example: In the photo below the stepper motor driver furthest to the right is responsible for power regulation to the X-Axis stepper motor. The X-Axis stepper motor controls the Left-Right movement of your extruder carriage.

If you notice a power failure or erratic behavior coming from one of your axes then you may have a bad or faulty stepper motor driver. The easiest way to verify this is to remove your electronics panel and take a look at your micro-controller. Sometimes its as easy as spotting a burnt spot on a stepper motor driver and other times you may have to swap out the stepper motor driver for another to verify that the original is not working. If you do not have an extra stepper motor driver to replace the suspected faulty driver you can pull out the faulty driver and also an adjacent driver and swap their places on the micro-controller. If the previously faulty axis is now working then you know that the driver that was previously in that slot is faulty.