BlueCast X-Nova

Exceptional post-printing flexibility. The ideal choice for stone pre-setting.

Introducing X-Nova, the latest resin innovation from BlueCast designed for a wide range of jewelry applications. This versatile resin boasts exceptional flexibility post-printing, making it an ideal choice for stone pre-setting. X-Nova is fully compatible with all LCD and DLP machines, including Novafab printers such (printing profiles LT-Dark 50u or LT-Burn 50u). With simplified cleaning and support removal processes, X-Nova is the perfect solution for businesses selling printed models or offering printing services. This newcomer isn’t here to replace our star, X-One, which remains unmatched after several and rigorous casting test against all available resins on the market. Its casting ease is simply unbeatable. The new resin simply feet different needs.

Main Features:

- Delivering prints with unparalleled sharpness and accuracy

- Flexible yet durable after UV exposure (Posturing is mandatory!)

- Compatible with both LCD and DLP printers

- Ideal for detailed filigrees or classic designs (not for the heavier models)

- Offers casting as seamless as our X-5 and X-10 resins

- Meets the needs of high-volume production effortlessly

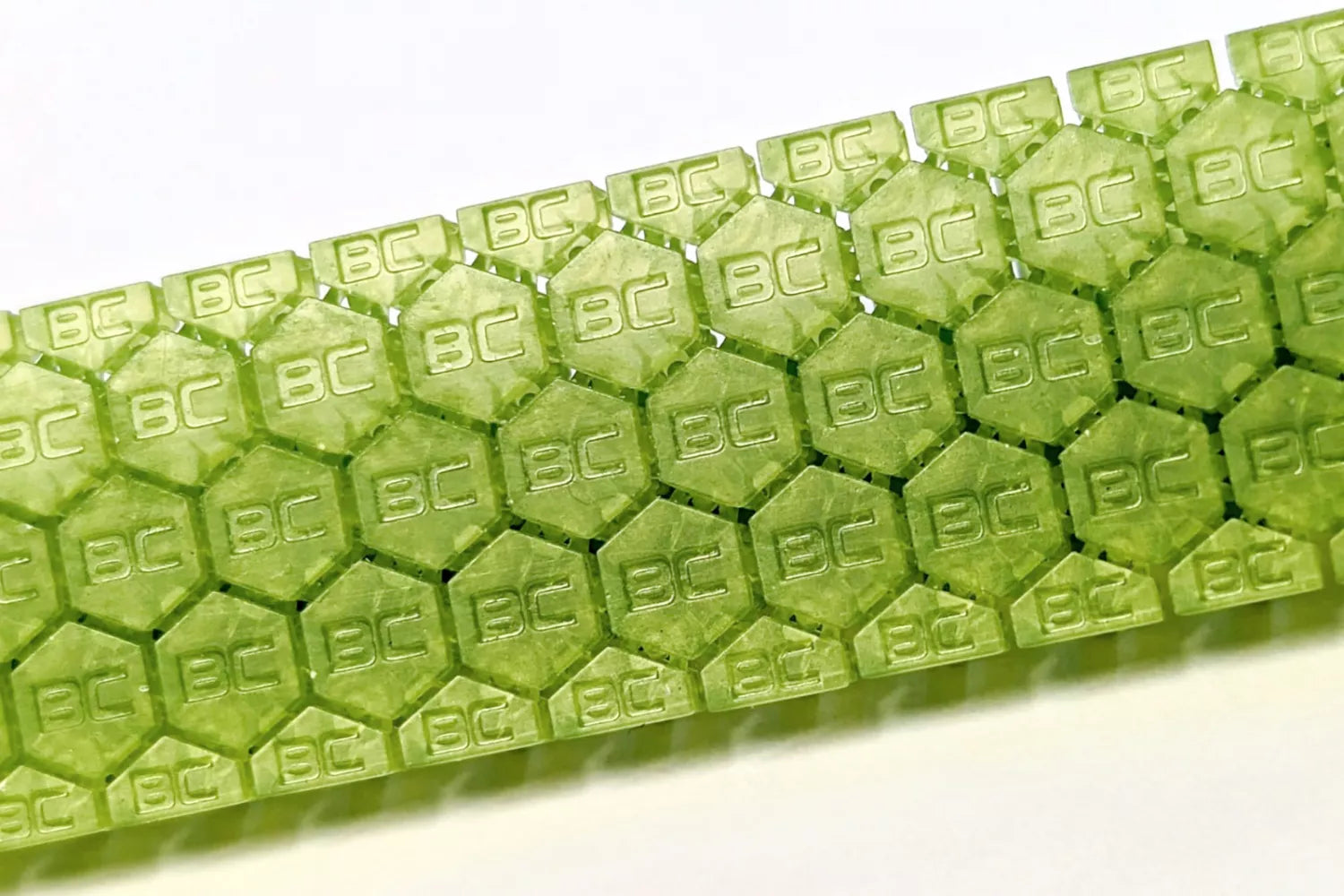

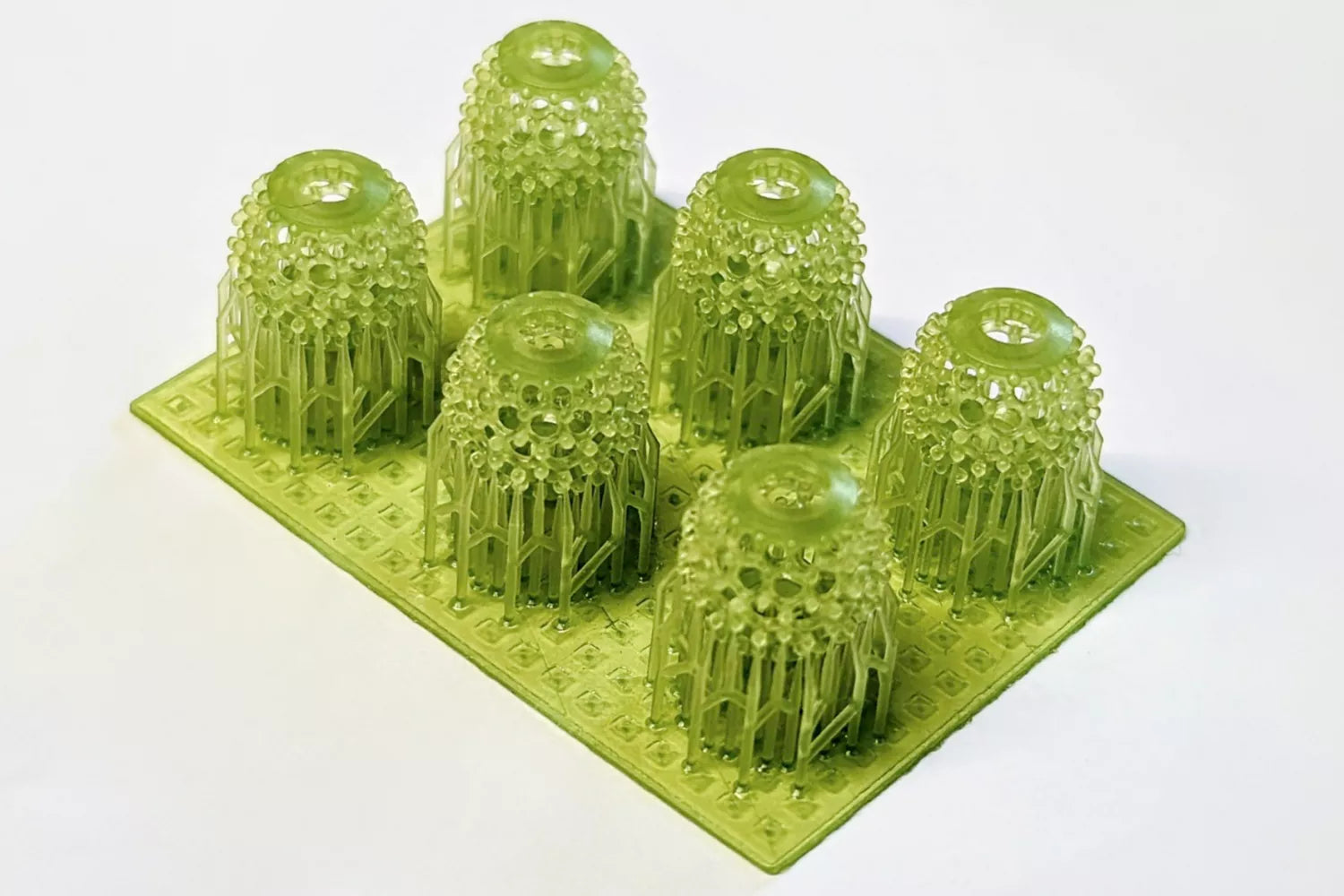

Resin Printed Sample

Before Print

- Before using the resin, shake the resin bottle for 60 seconds. If the resin has been sitting in the tank, use a silicone spatula to ensure it is thoroughly mixed.

- If not mandatory various methods can be used to heat the resin, such as microwave ovens (never exceeding 30 seconds), ultrasonic cleaners, hot air, baby bottle warmer, etc. The optimal operating range is from 20 to 30°C.

- To enhance platform model adhesion, you can sand the build platform using 150/200 grade sandpaper, and pre-heat the resin before printing.

- Check the Z offset and perform calibration if necessary.

- It is recommended to filter the resin after each print cycle and store it in its original container to preserve its quality and prevent any changes in its characteristics.

- Remove the prints from the build plate.

- Wash the prints in 90% to 99% ethyl alcohol or IPA for 5 minutes approximately.

- Dry the patterns using compressed air for optimal results.

- Put the patterns inside a UV oven and let it cure for 50 to 60 minutes, considering the lamp power and pattern size. The UV curing process is complete when the pattern color becomes lighter.